Ceramic Glaze

Ceramic glaze is an impervious layer or coating of a vitreous substance which has been fused to a pottery body through firing.

Glaze can serve to color, decorate or waterproof an item.

Raw Glazes and Fritted Glazes

Regardless of their color, product/process type, or final surface texture, glazes are described as either fritted or raw. Raw glazes are made by blending synthetic and natural materials such as quartz, clays, oxides, carbonates, and feldspars.

On the other hand, fritted glazes contain a specific percentage of pre-melted frit or glass. These are utilized when firing or compositional demands rule out the possibility of making raw glazes.

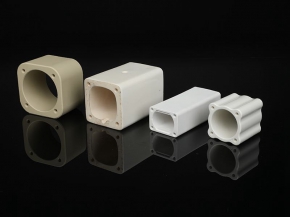

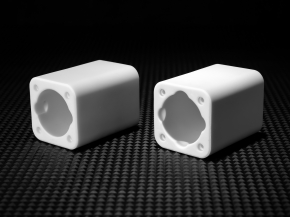

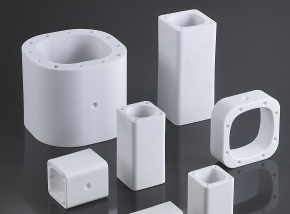

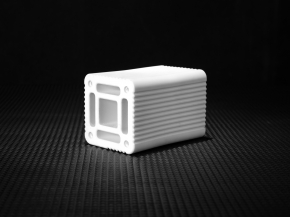

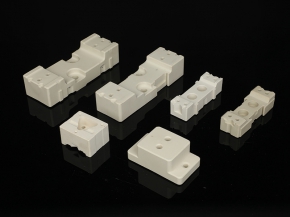

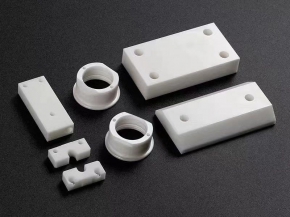

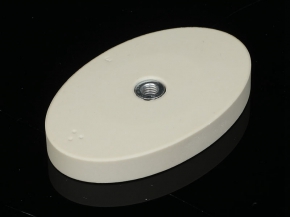

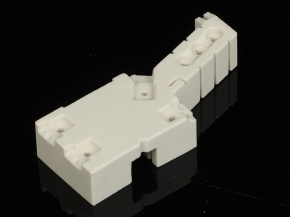

Ceramic Applcation:

1. Make the ceramic part impermeable to liquid and gas;

2. Cover the surface of the green body to improve the aesthetics;

3. Prevent contamination of the green body, improve the electrical properties of the product, and resist chemical erosion;

4. Integrate with the green body to increase the strength and hardness of the ceramic.

Generally, glaze materials are applied as a water-based suspension using spraying or dipping techniques. Mechanization is a common technique, although several manual and craft methods are also available. In some cases, dry and electrostatic methods are used.

Glazes are applied to a number of substrates, such as tableware, sanitaryware, giftware, refractories, tiles, electrical porcelain, and engineering ceramics. Additionally, they are applied to cement and graphite, that are less common substrates.