The Main Application of Si3N4 Ceramic

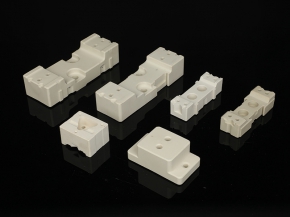

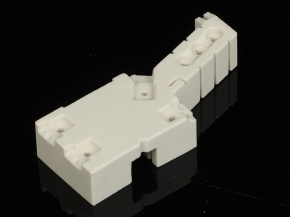

For mechanical industry

Silicon nitride ceramics can be used as turbine blades, mechanical seal rings, high-temperature bearings, high-speed cutting tools, permanent molds, etc. in the machinery industry. Many devices in the traditional machinery industry use metal materials. Since the metal will be corroded, the reliability and service life of these devices are greatly affected. Silicon nitride ceramic materials have excellent wear resistance, corrosion resistance, and high temperature thermal shock resistance, can replace metal materials in the field of machinery industry.

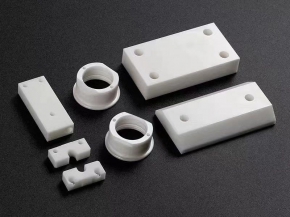

For Superfine Grinding

Silicon nitride ceramics are covalent compounds whose bonding mainly relies on covalent bonds between atoms. The prepared material itself has high hardness and wear resistance. Silicon nitride has high hardness, second only to a few superhard materials such as diamond and cubic boron nitride, with low friction coefficient and self-lubricating properties. In the ultra-fine powder and food processing industries, the performance of silicon nitride ceramic grinding balls is higher than that of traditional grinding balls, with higher hardness and superior wear resistance.

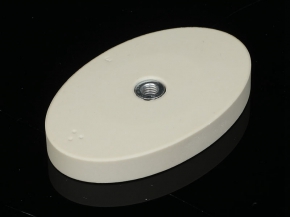

For Ceramic Substrate

With the rapid development of information technology, the integration level of integrated circuits is getting higher and higher, and the wiring density is getting higher and higher. If the electronic packaging substrate cannot dissipate heat in time, a large amount of heat will accumulate on the integrated circuit, which will eventually lead to its failure and damage. Therefore, the thermal conductivity of the substrate is extremely important. Silicon nitride ceramics are structural ceramic materials with the best comprehensive performance. The theoretical thermal conductivity of single crystal silicon nitride can reach more than 400W·m-1, and it has the potential to become a high thermal conductivity substrate. In addition, its excellent mechanical properties and good high thermal conductivity potential make silicon nitride ceramics expected to make up for the existing the lack of substrate materials such as alumina and aluminum nitride has great market prospects in the application of electronic packaging substrates.